SiC

Third Generation

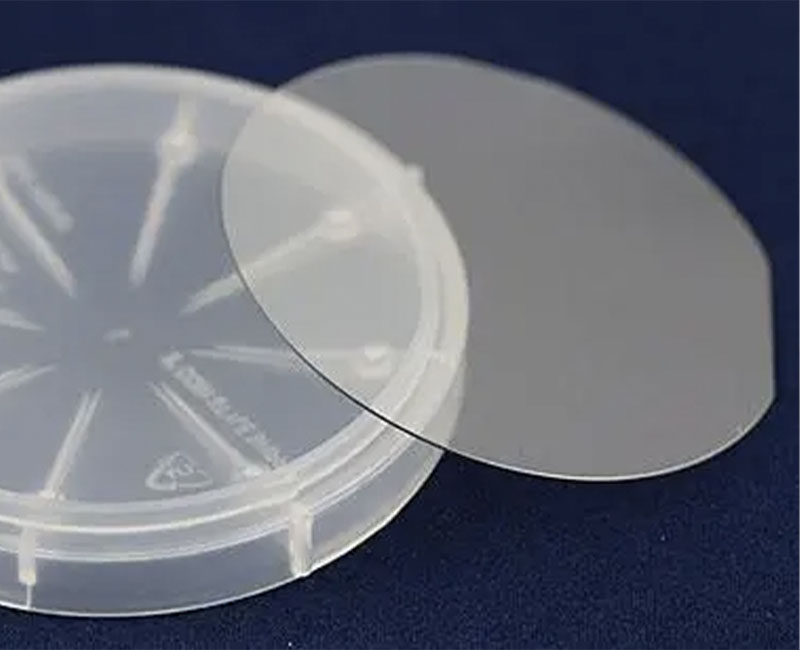

The provided text appears to be specifications for silicon carbide (SiC) wafers of various sizes (2 inches, 3 inches, 4 inches, and 6 inches). These wafers are semiconductor materials used in the prod..

Description

The provided text appears to be specifications for silicon carbide (SiC) wafers of various sizes (2 inches, 3 inches, 4 inches, and 6 inches). These wafers are semiconductor materials used in the production of high-temperature, high-frequency, and high-power electronic devices, particularly power chips for applications such as solar inverters, wind power generation, hybrid vehicles, and electric cars.

Here's a summary of the information for each wafer size:

|

Grade

|

Production

|

Research grade

|

Dummy Grade

|

||

|

Diameter

|

50.8 mm ±0.38 mm (2 inches)

|

||||

|

Thickness

|

330 μm ±25 μm

|

||||

|

Crystal Orientation

|

On axis : <0001> ±0.5° for 6H-N/4H-N/4H-SI/6H-SI

|

Off axis: 4.0° toward 1120 ±0.5° for 4H-N/4H-SI

|

|||

|

Dislocation Density (cm-2)

|

≤5

|

≤15

|

≤50

|

||

|

Resistivity (Ω·cm)

|

4H-N

|

0.015~0.028 Ω·cm

|

|||

|

6H-N

|

0.02~0.1

|

||||

|

4/6H-SI

|

>1E5

|

(90%) >1E5

|

|||

|

Main Flat Orientation

|

{10-10} ±5.0°

|

||||

|

Main Flat Length (mm)

|

15.9 ±1.7

|

||||

|

Minor Flat Length (mm)

|

8.0 ±1.7

|

||||

|

Minor Flat Orientation

|

Silicon face up: 90° CW. from Prime flat ±5.0°

|

||||

|

Edge Exclusion

|

1 mm

|

||||

|

TTV/Bow/Warp (um)

|

≤15 / ≤25 / ≤25

|

||||

|

Surface Roughness

|

Polish Ra≤1 nm

|

||||

|

CMP Ra≤0.5 nm

|

|||||

|

Cracks (Bright light observation) #

|

None

|

None

|

1 allowed, ≤1 mm

|

||

|

Hexagonal Holes (Bright light observation) *

|

Cumulative area≤1%

|

Cumulative area≤1%

|

Cumulative area≤3%

|

||

|

Polymorphism (Bright light observation) *

|

None

|

Cumulative area≤2%

|

Cumulative area≤5%

|

||

|

Scratches (Bright light observation) *

|

3 scratches to 1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

8 scratches to 1×wafer diameter cumulative length

|

||

|

Chipping #

|

None

|

3 allowed, ≤0.5 mm each

|

5 allowed, ≤1 mm each

|

||

|

Surface Contamination (Bright light observation)

|

None

|

||||

3-Inch Specification

|

Grade

|

Production

|

Research grade

|

Dummy Grade

|

||

| Diameter | 76.2±0.38mm (3 inches) | ||||

|

Thickness

|

350 μm±25μm

|

||||

|

Crystal Orientation

|

On axis : <0001>±0.5° for 6H-N/4H-N/4H-SI/6H-SI

|

Off axis:4.0° toward 1120±0.5° for 4H-N/4H-SI

|

|||

|

Dislocation Density (cm-2)

|

≤5

|

≤15

|

≤50

|

||

|

Resistivity (Ω·cm)

|

4H-N

|

0.015~0.028 Ω·cm

|

|||

|

6H-N

|

0.02~0.1

|

||||

|

4/6H-SI

|

>1E5

|

(90%) >1E5

|

|||

|

Main Flat Orientation

|

{10-10}±5.0°

|

||||

|

Main Flat Length (mm)

|

22.2 mm±3.2 mm

|

||||

|

Minor Flat Length (mm)

|

11.2 mm±1.5 mm

|

||||

|

Minor Flat Orientation

|

Silicon face up: 90° CW. from Prime flat ±5.0°

|

||||

|

Edge Exclusion

|

2 mm

|

||||

|

TTV/Bow/Warp (um)

|

≤15 /≤25 /≤35

|

||||

|

Surface Roughness

|

Polish Ra≤1 nm

|

||||

|

CMP Ra≤0.5 nm

|

|||||

|

Cracks (Bright light observation) #

|

None

|

1 allowed,≤1 mm

|

1 allowed, ≤2 mm

|

||

|

Hexagonal Holes (Bright light observation) *

|

Cumulative area≤1 %

|

Cumulative area≤1 %

|

Cumulative area≤3 %

|

||

|

Polymorphism (Bright light observation)*

|

None

|

Cumulative area≤2 %

|

Cumulative area≤5%

|

||

|

Scratches (Bright light observation)*

|

3 scratches to1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

8 scratches to 2×wafer diameter cumulative length

|

||

|

Chipping #

|

None

|

3 allowed,≤0.5 mm each

|

5 allowed,≤1 mm each

|

||

|

Surface Contamination (Bright light observation)

|

None

|

||||

4-Inch Specification

|

Grade

|

Production

|

Research grade

|

Dummy Grade

|

||

|

Diameter

|

100±0.5mm (4 inches) | ||||

|

Thickness

|

350 μm±25μm

|

||||

|

Crystal Orientation

|

On axis : <0001>±0.5° for 6H-N/4H-N/4H-SI/6H-SI

|

Off axis:4.0° toward 1120±0.5° for 4H-N/4H-SI

|

|||

|

Dislocation Density (cm-2)

|

≤5

|

≤15

|

≤50

|

||

|

Resistivity (Ω·cm)

|

4H-N

|

0.015~0.028 Ω·cm

|

|||

|

6H-N

|

0.02~0.1

|

||||

|

4/6H-SI

|

>1E5

|

(90%) >1E5

|

|||

|

Main Flat Orientation

|

{10-10}±5.0°

|

||||

|

Main Flat Length (mm)

|

32.5±2.5mm

|

||||

|

Minor Flat Length (mm)

|

18.0±2mm

|

||||

|

Minor Flat Orientation

|

Silicon face up: 90° CW. from Prime flat ±5.0°

|

||||

|

Edge Exclusion

|

3mm

|

||||

|

TTV/Bow/Warp (um)

|

≤15 /≤25 /≤40

|

||||

|

Surface Roughness

|

Polish Ra≤1 nm

|

||||

|

CMP Ra≤0.5 nm

|

|||||

|

Cracks (Bright light observation) #

|

None

|

1 allowed,≤2 mm

|

Cumulative length ≤ 10mm, single length≤2mm

|

||

|

Hexagonal Holes (Bright light observation) *

|

Cumulative area≤1 %

|

Cumulative area≤1 %

|

Cumulative area≤3 %

|

||

|

Polymorphism (Bright light observation)*

|

None

|

Cumulative area≤2 %

|

Cumulative area≤5%

|

||

|

Scratches (Bright light observation)*

|

3 scratches to1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

||

|

Chipping #

|

None

|

3 allowed,≤0.5 mm each

|

5 allowed,≤1 mm each

|

||

|

Surface Contamination (Bright light observation)

|

None

|

||||

6-Inch Specification

|

Grade

|

Production

|

Research grade

|

Dummy Grade

|

||

|

Diameter

|

150±2.0mm (6 inches) | ||||

|

Thickness

|

350 μm±25μm

|

||||

|

Crystal Orientation

|

On axis : <0001>±0.5° for 6H-N/4H-N/4H-SI/6H-SI

|

Off axis:4.0° toward 1120±0.5° for 4H-N/4H-SI

|

|||

|

Dislocation Density (cm-2)

|

≤5

|

≤15

|

≤50

|

||

|

Resistivity (Ω·cm)

|

4H-N

|

0.015~0.028 Ω·cm

|

|||

|

4/6H-SI

|

>1E5

|

||||

|

Main Flat Orientation

|

{10-10}±5.0°

|

||||

|

Main Flat Length (mm)

|

47.5 mm±2.5 mm

|

||||

|

Edge Exclusion

|

3mm

|

||||

|

TTV/Bow/Warp (um)

|

≤15 /≤40 /≤60

|

||||

|

Surface Roughness

|

Polish Ra≤1 nm

|

||||

|

CMP Ra≤0.5 nm

|

|||||

|

Cracks (Bright light observation) #

|

None

|

1 allowed,≤2 mm

|

Cumulative length ≤ 10mm, single length ≤ 2mm

|

||

|

Hexagonal Voids (Bright light observation) *

|

Cumulative area ≤ 1 %

|

Cumulative area ≤ 2 %

|

Cumulative area ≤ 5%

|

||

|

Polymorphism (Bright light observation) *

|

None

|

Cumulative area ≤ 2 %

|

Cumulative area ≤ 5%

|

||

|

Scratches (Bright light observation) *

|

3 scratches to 1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

5 scratches to 1×wafer diameter cumulative length

|

||

|

Chipping #

|

None

|

3 allowed,≤0.5 mm each

|

5 allowed,≤1 mm each

|

||

|

Surface Contamination (Bright light observation)

|

None

|

||||